The AWV Story

In 1904 American Warming and Ventilating was created as a division of American Furnace and Foundry Company in Bloomington, Indiana. The company began as a regional contractor that installed gravity heating systems.

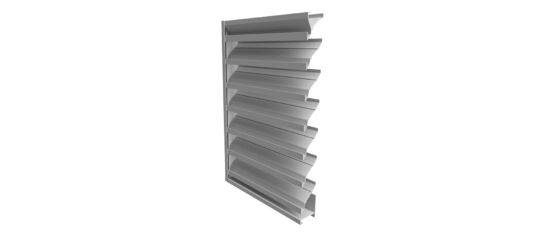

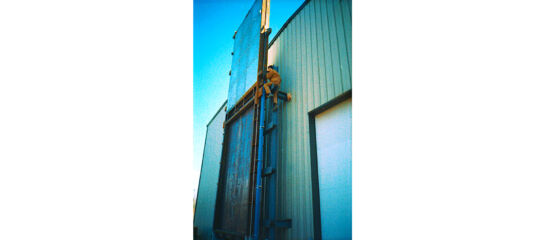

Today, architects, mechanical engineers, contractors and facility owners rely on American Warming and Ventilating to meet their ever-changing damper and louver designs and cost requirements through product innovation and technological advancement.

Our headquarters, located in Bowling Green, Ohio, is the central hub, but our vast representative base throughout the nation is available to help you find the right product for your project.

1904

1940's

1954

1963

1968

1978

1980

1981

1986

1987

1990

2007

TODAY